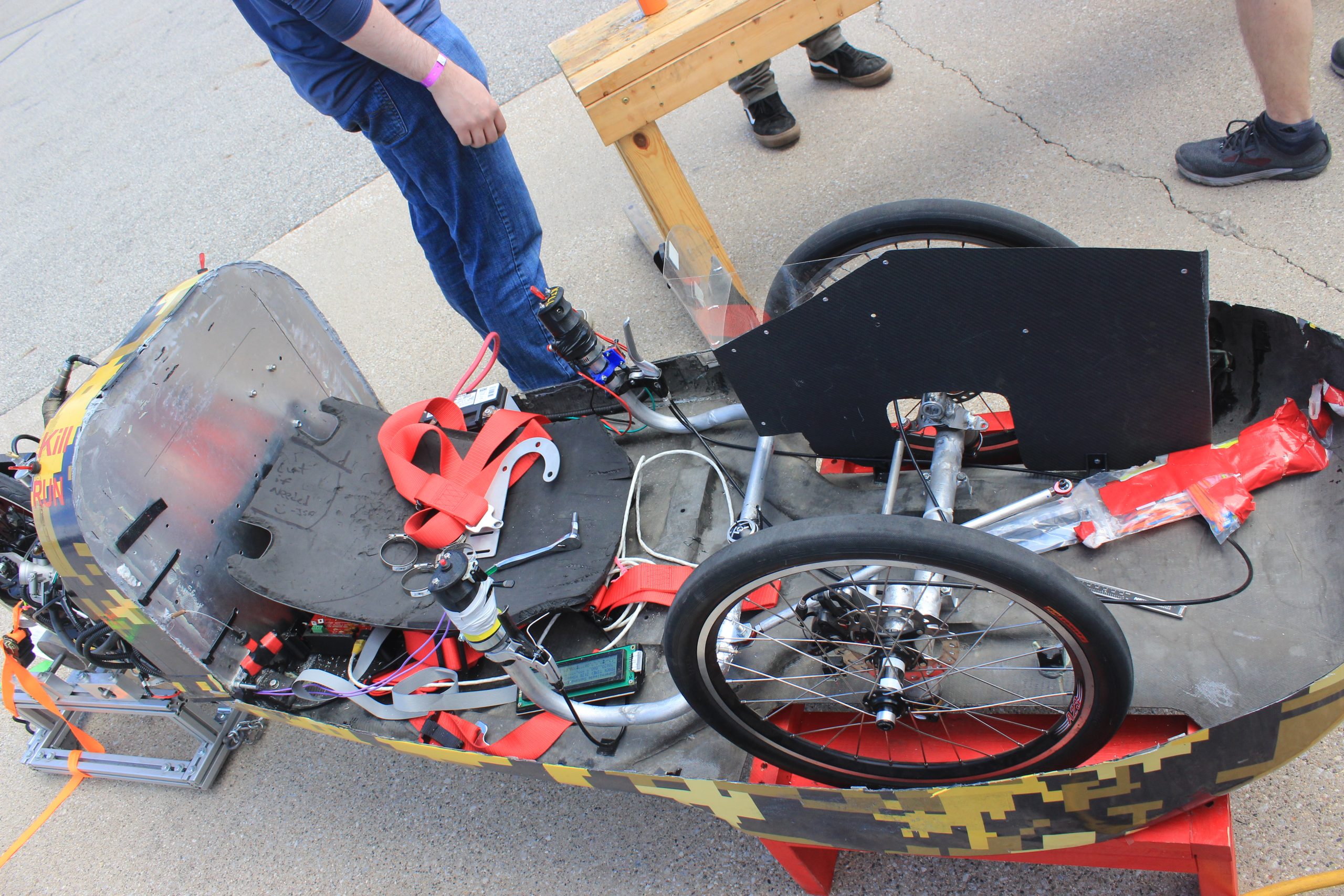

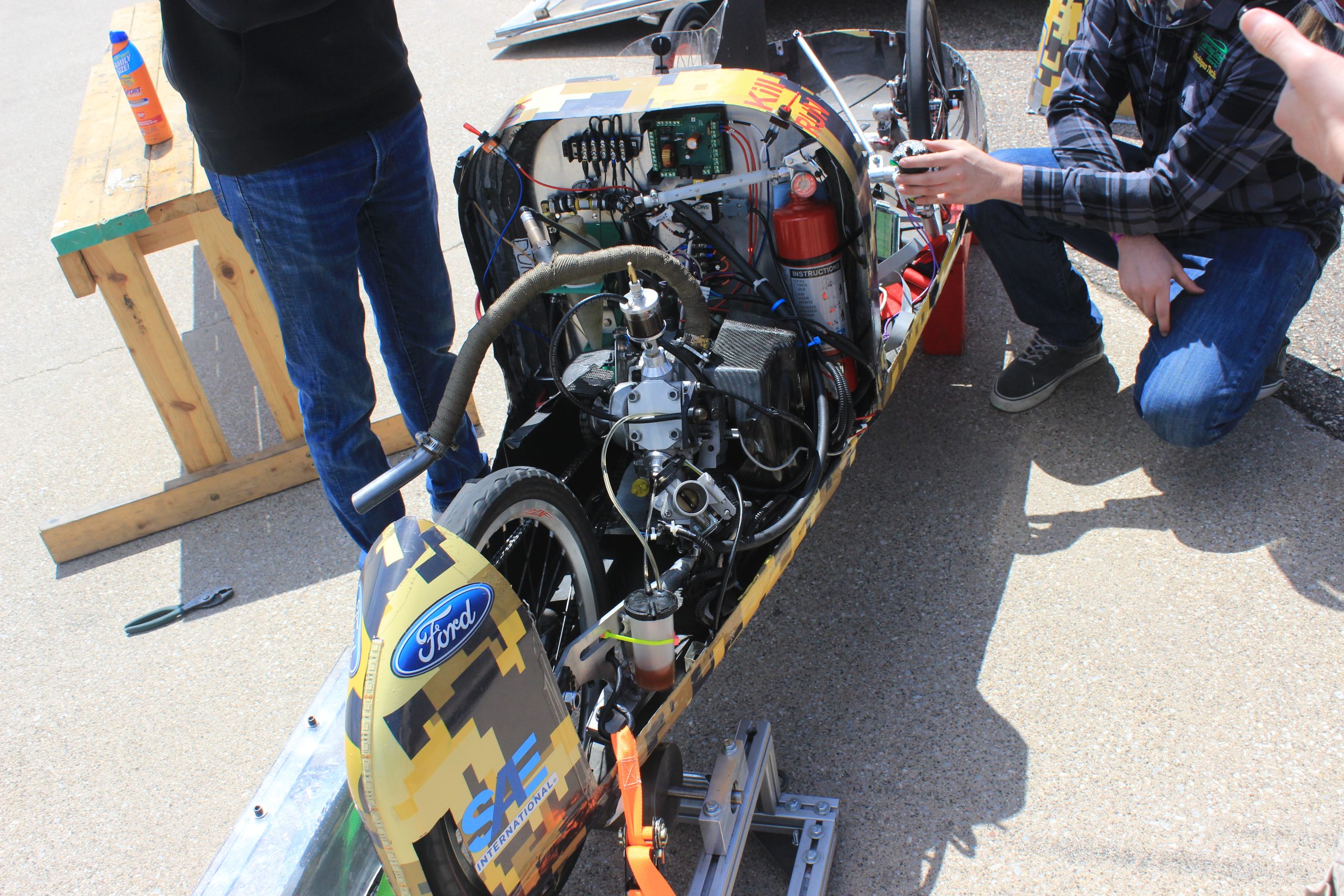

The Supermileage Systems Enterprise is one of Michigan Tech’s Advanced Motorsports Enterprises. We are a student-led organization that builds a single occupant, high efficiency vehicle that competes in the Shell Eco-marathon competition.

We are always interested in bringing new members to the team! To begin this process, take a look at our contact page that will help you get in touch with our team and our calendar that shows our major events.

Visit our Facebook and Instagram pages for up-to-date information on about our team, pictures on our projects, and upcoming events.